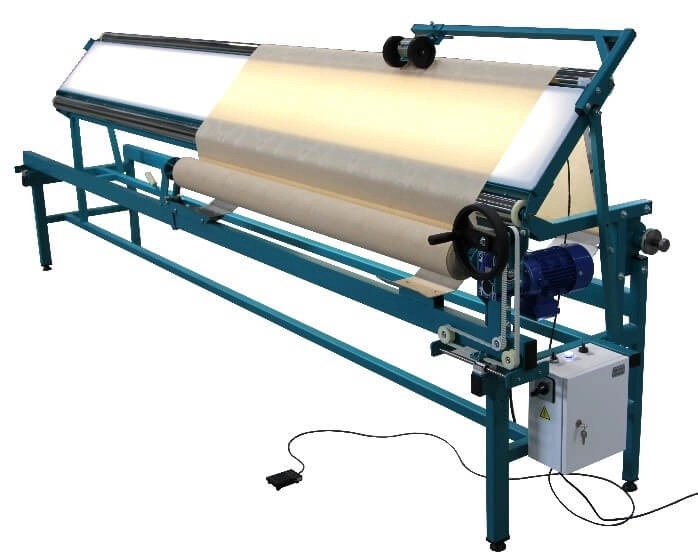

Fabric cutting tables and other machinery for roller blinds production

(professional fabric cutting tables and tailor-made cutting solutions, inspection hoists, positioning systems, fabric winding devices etc)

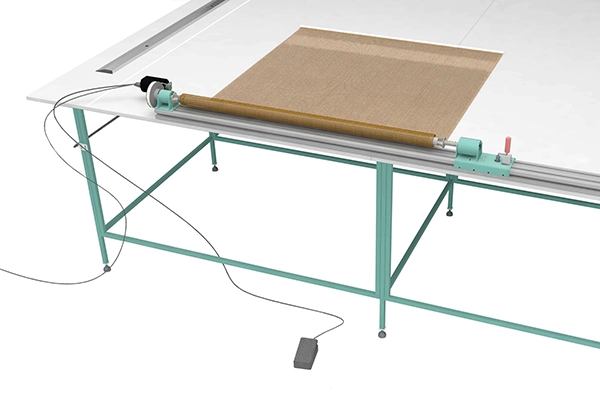

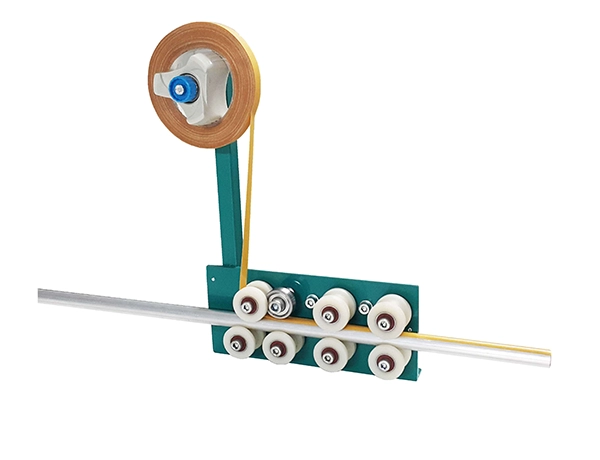

Industrial fabric cutting table with electric rotary knife (series R/RS)

- Suitable for cutting any fabrics

- Switch from blade to ultrasound knife and back in 1 second

- Two-sided pneumatic clamping of fabric

- Fabric edge sensor

- Automatic clamping and cutting cycle

- Automatic return of the knife to its initial position without any risk of an uncontrolled contact with fabric

- Sealing edge of synthetic materials